We design robotic lines that will increase the capacity of your production and your competitiveness. Top-class and highly efficient robots can work nonstop 24/7 throughout the year. You can be 100% confident about the accuracy of the produced parts and the precision of our work. We will give your ideas a clear shape and will turn them into a technically reliable and smart solution. Difficult physical activities and dangerous activities are carried out by a robot.

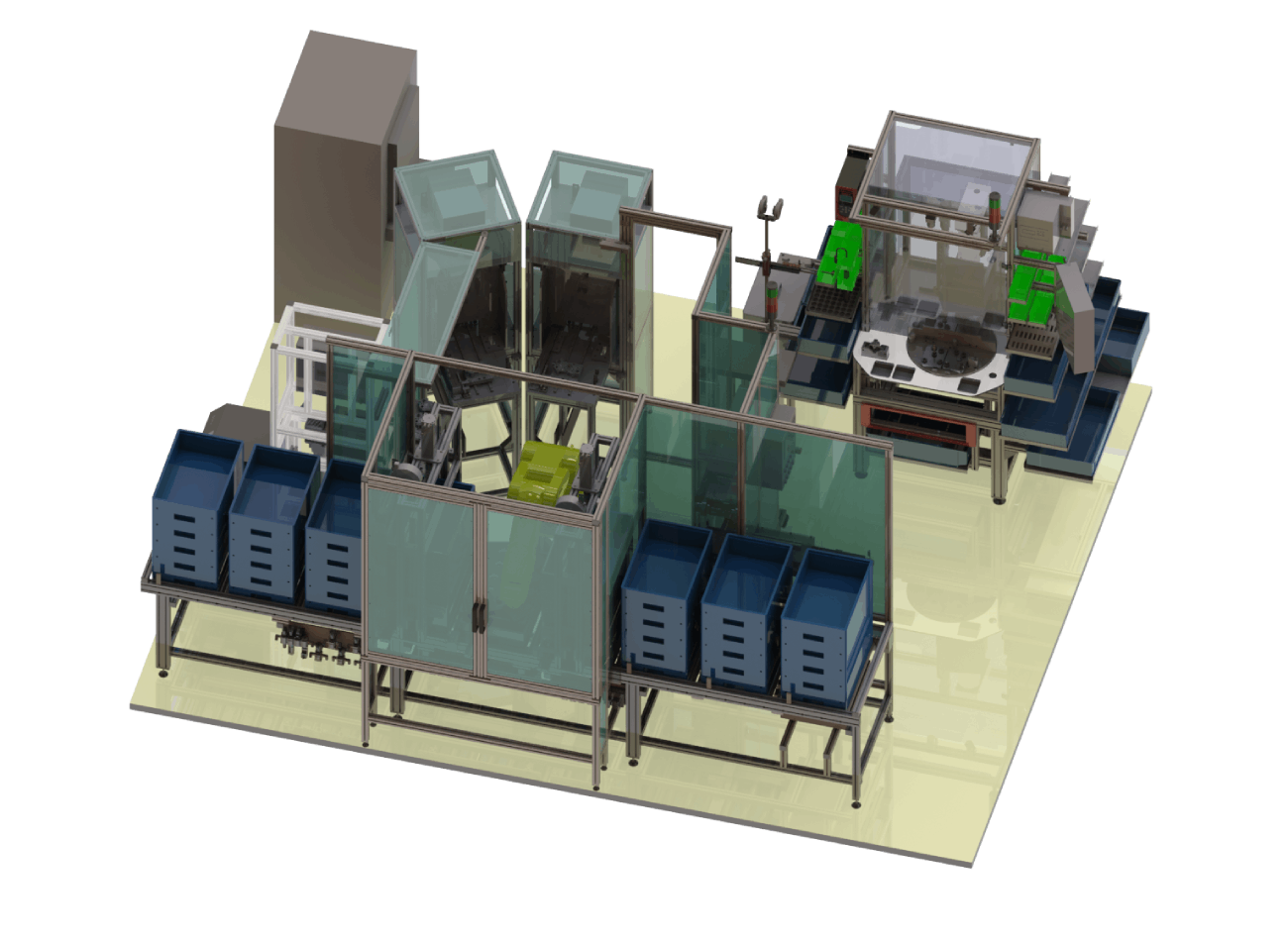

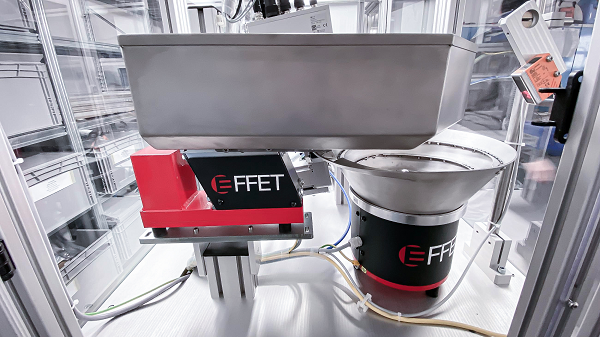

Robotic Assembly Cells

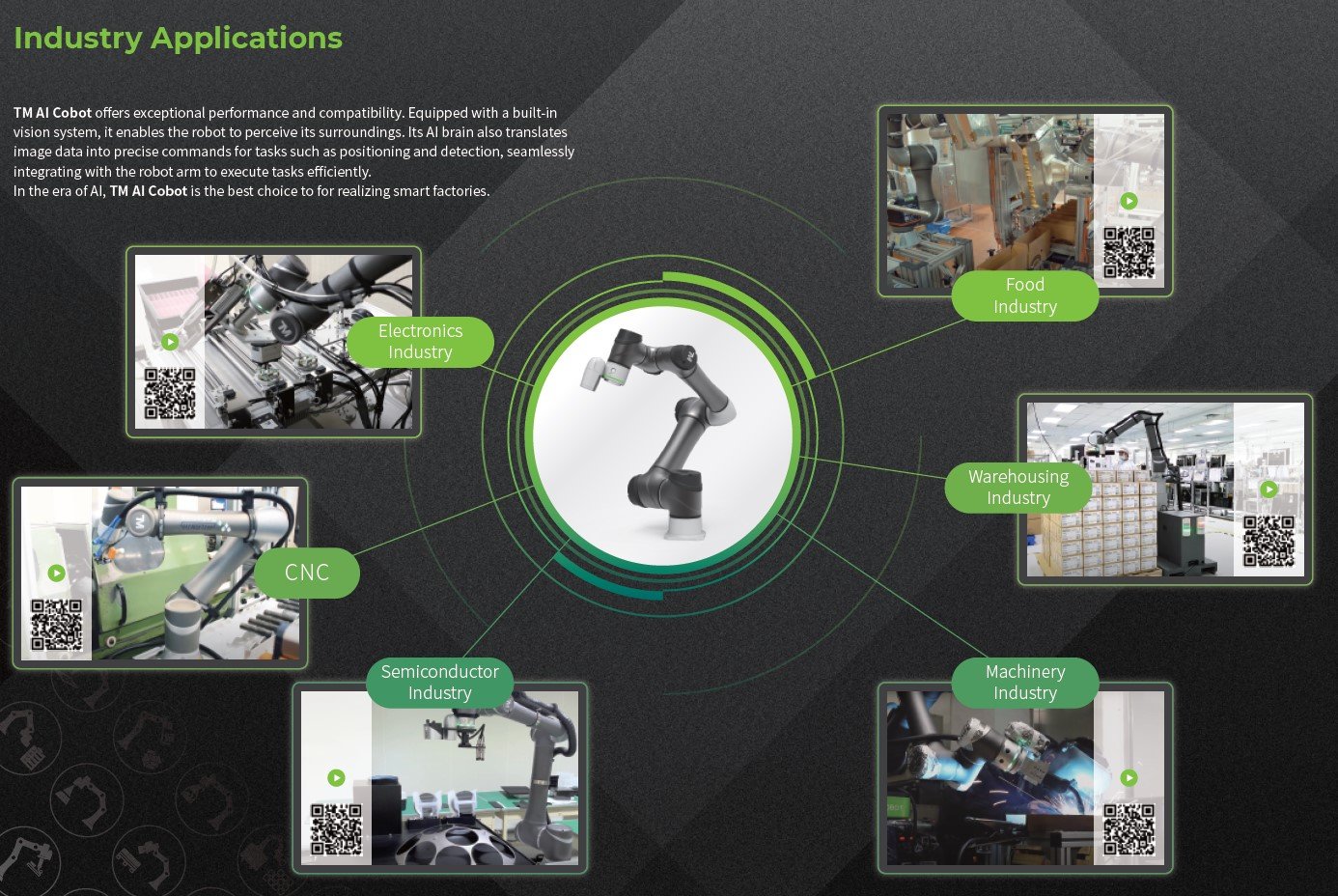

Collaborative Robots

Robotic Manipulation

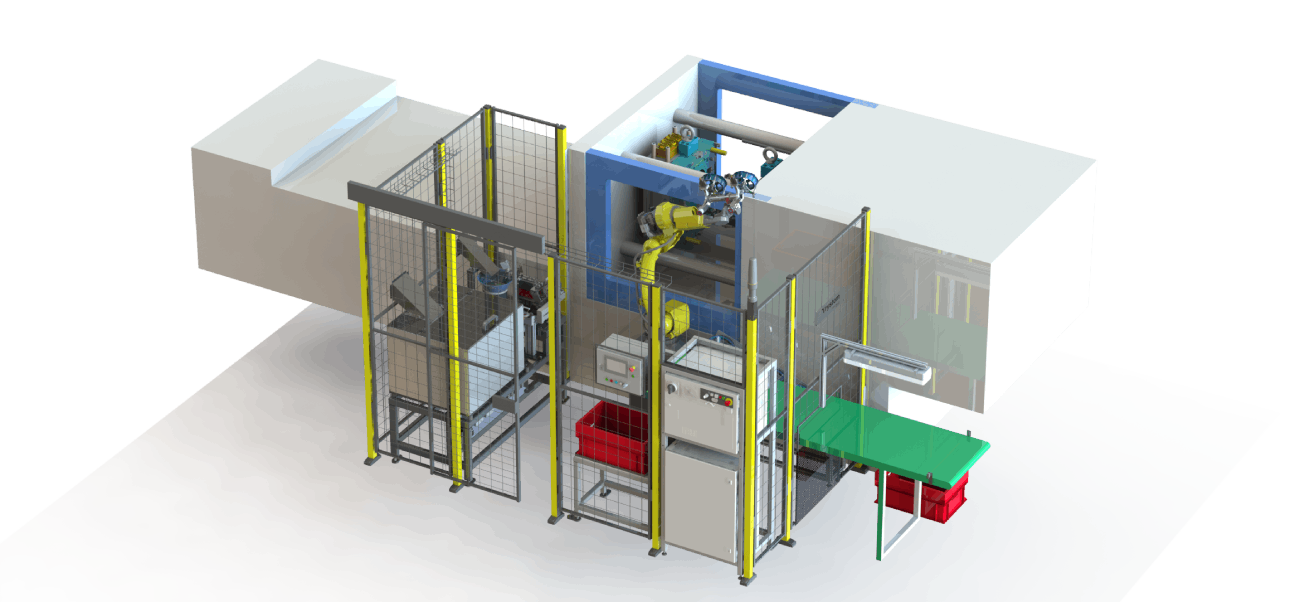

Robotization for Forming Machines

Robotization for Injection Moulding Machines