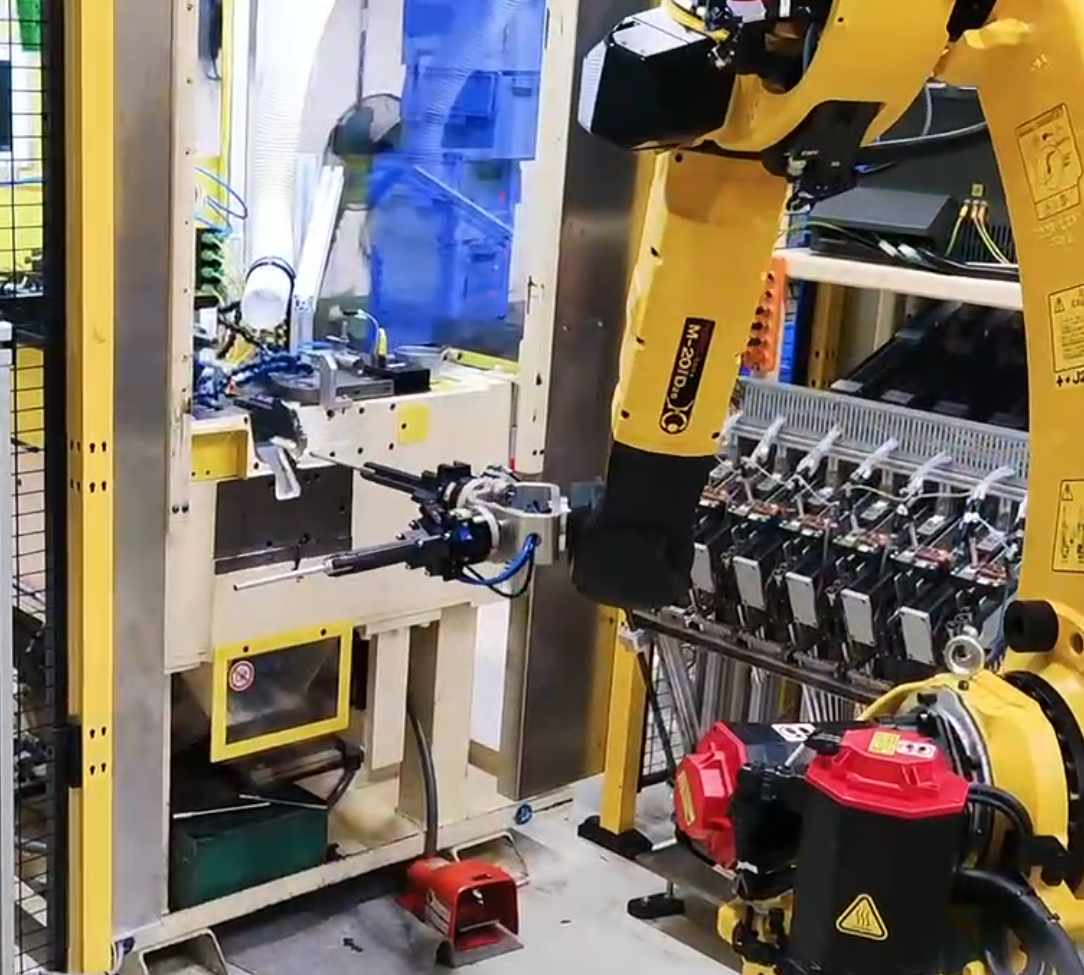

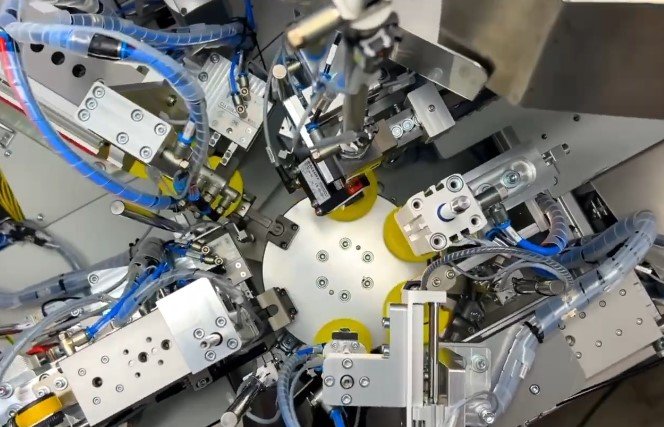

New energy, new challenges, new Trystom 💪

Spring is a symbol of awakening, newness, energy🌸🍀. At Trystom, we started a series of trainings in the spring to bring these attributes to our company. We have clocked 32 hours of project management training with an amazing trainer Michaela Duchkova. 👍🙏And that they were bombs💥. We have a plan on what and how to improve and we're really working on it. 💪 We're having fun, we want change, we're being honest with ourselves. We come up with and implement action steps 💹 The energy is indescribable. It has to be experienced. In a month we continue. I will write how it went.