Search term must have more than 2 characters.

MEASURING THE DIAMETER AND LENGTH BY MEANS OF A DIGITAL TELECENTRIC CAMERA

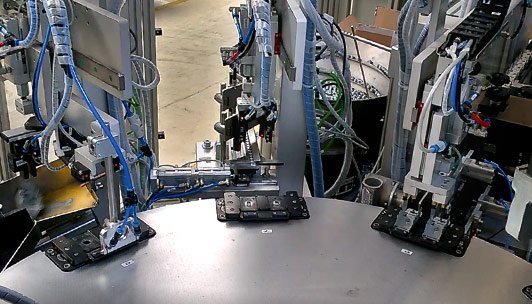

The deburring station is part of a robotic line producing end pieces. The station serves for deburring the end of an aluminium tube after the forming operation. The robot or manipulator inserts the tube into the machine and pneumatic fastening takes place. The deburring tool is located on an electric carriage and its trajectory can be fully configured from the PLC. After the end of the deburring operation, the pneumatic jaws are loosened and the deburred product is removed from the station.

CAMERA CONTROL – PROFILOMETER MEASUREMENTS

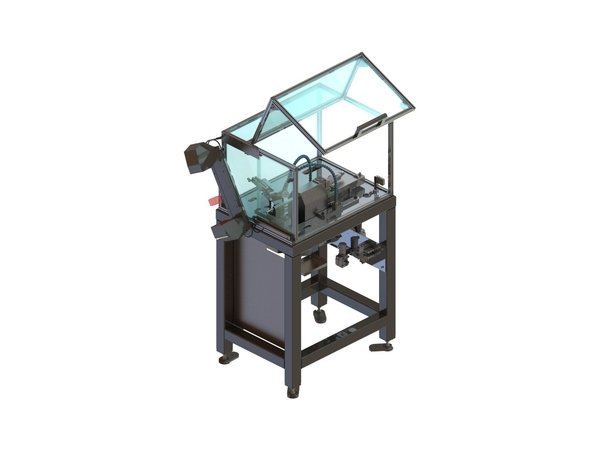

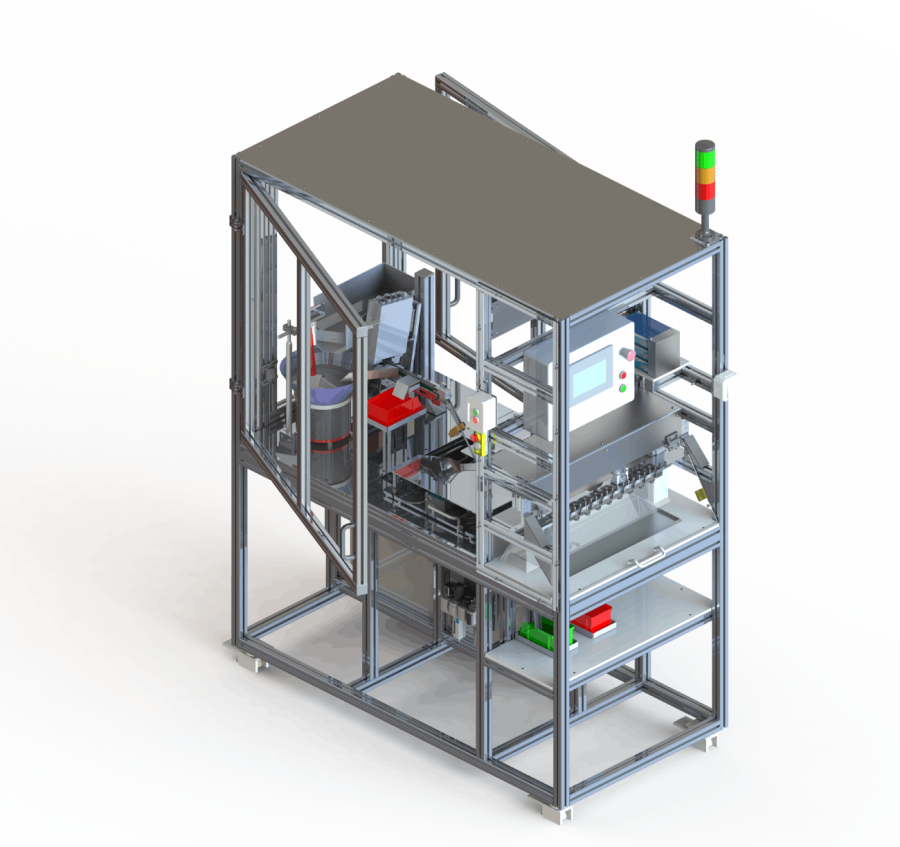

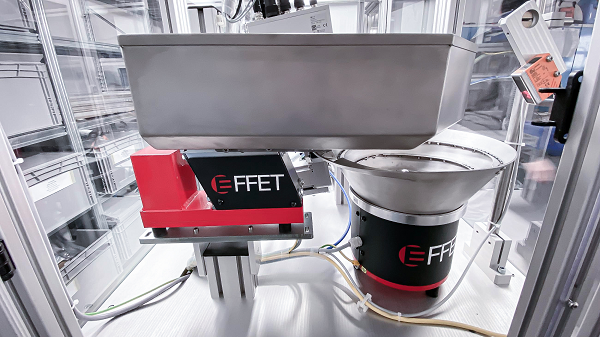

A valve sorting machine serves for managing the quality and type of a valve. The station is designed as fully automated. After the replenishment, the parts are checked by means of three gauges with the accuracy of 0.01 mm at an interval of 3 parts per second and, subsequently, are precisely dosed into bags and conserved.

The machine consists of a basic frame made of aluminium profiles and is located on the wheels. On the frame, there are aluminium boards serving as the basis for all parts of the machine. The machine is logically divided into three functional parts. In the first position, the parts are poured into the vibration feeder from which they are directed and transferred to other positions where quality control takes place.

Finally, the parts are dosed into the prepared bags and conserved through an automated dosage of grease. The machine is controlled by means of PLC Simatic and can be controlled or set with the use of a touch HMI panel.

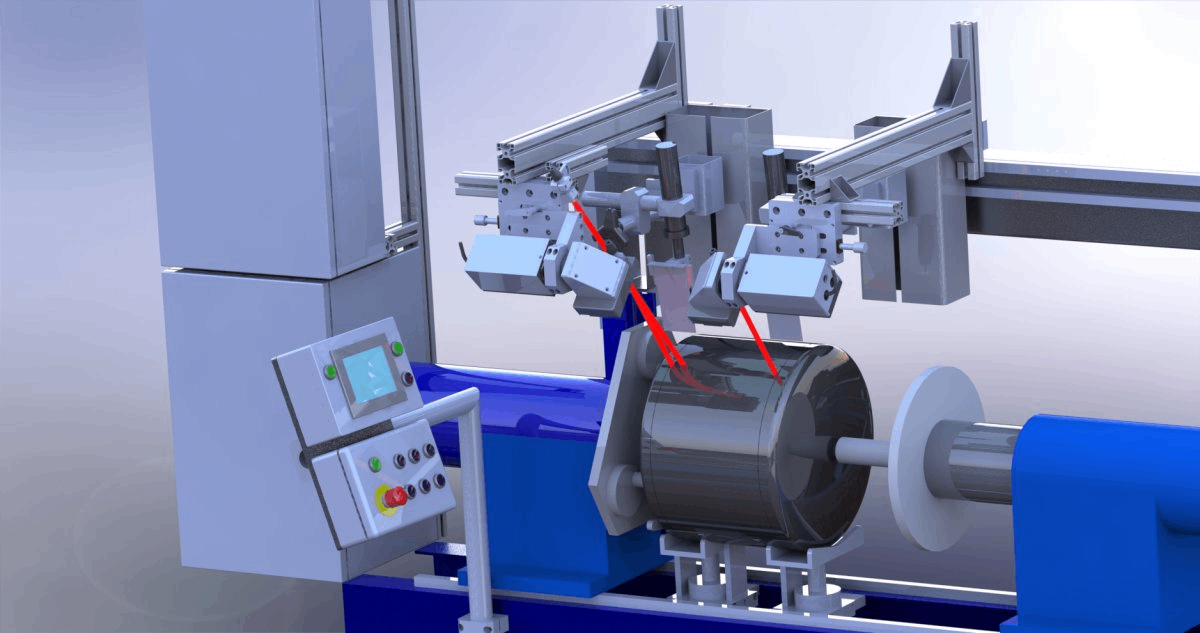

CAMERA GUIDING OF WELDING BURNERS

The implementation of the project constitutes automation of the welding cycle of four welding machines for the welding of the peripheral coatings of air reservoirs.

The project was implemented for our Czech branch Frauenthal automotive in Hustopeče.

The welding machines were additionally equipped with a specially designed camera guiding system for the precise and unattended positioning of the welding burner nozzles during the welding of the peripheral weld joint of the pressure vessel. The line of the removal of the peripheral coat and the air vent bottom is accentuated through infrared dim light LED units and scanned by the infrared camera sensor KEYENCE.